CNC Machining

• Specialized, experienced, advanced CNC machine shops

• Parts as Fast as 3 days

Request a Quote Now

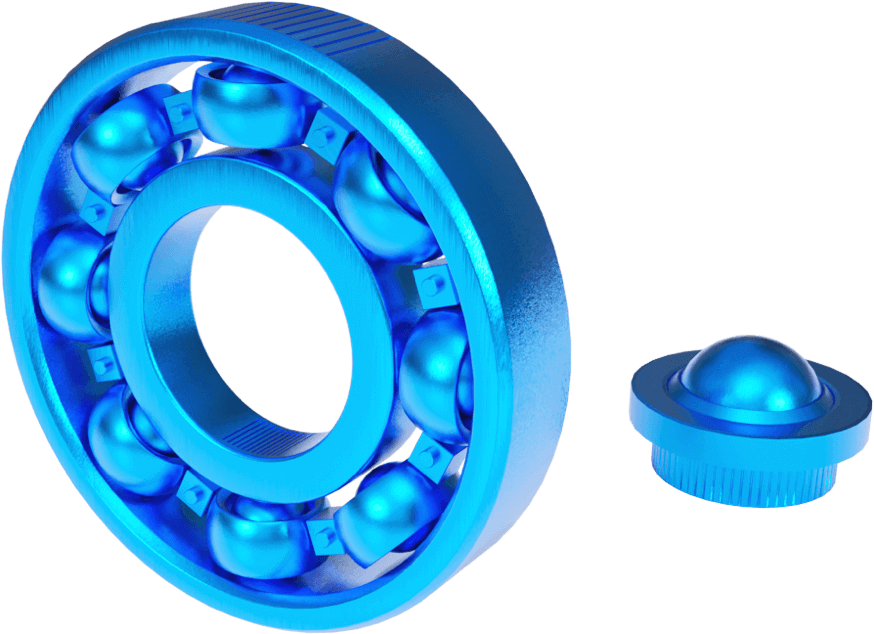

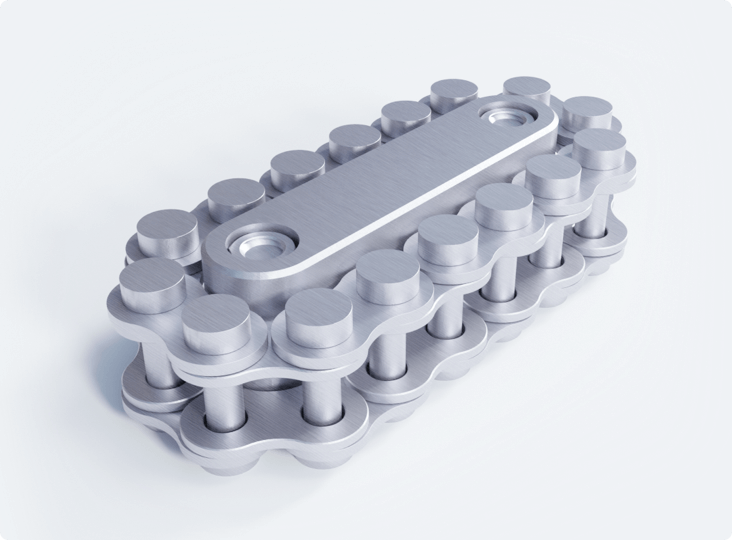

CNC Machining Processes

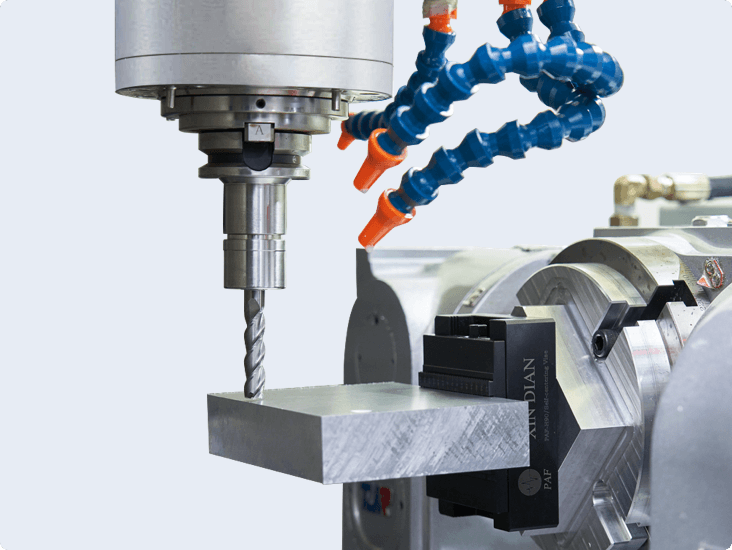

CNC Milling

3-, 4- & full 5-axis CNC milling

High Precision, High Efficiency

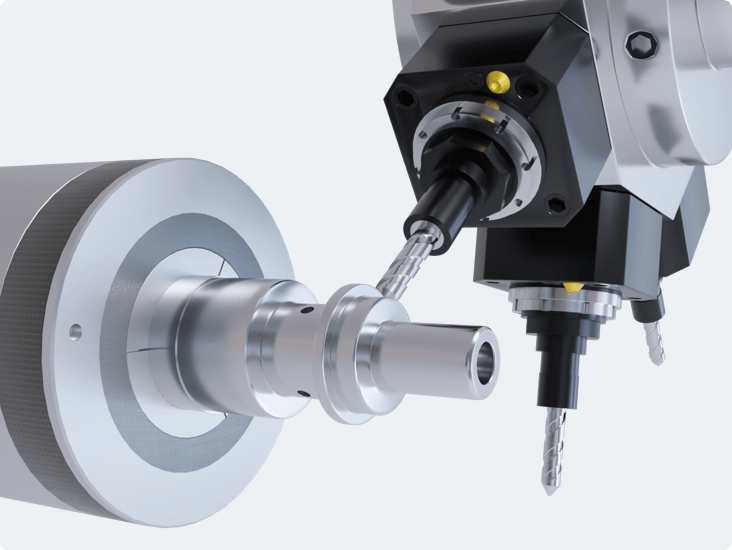

CNC Turning

CNC turning, Mill-turning center

High Precision, High flexibility

Surface Finishing

Various surface finishing options

Bead blasting, Anodizing, Polishing and etc

CNC Machining Capabilities

CNC Machining Materials

- Aluminum

- • Aluminum 6061 >

- • Aluminum 7075 >

- Copper

- • Brass - H59 >

- • Copper - T2 >

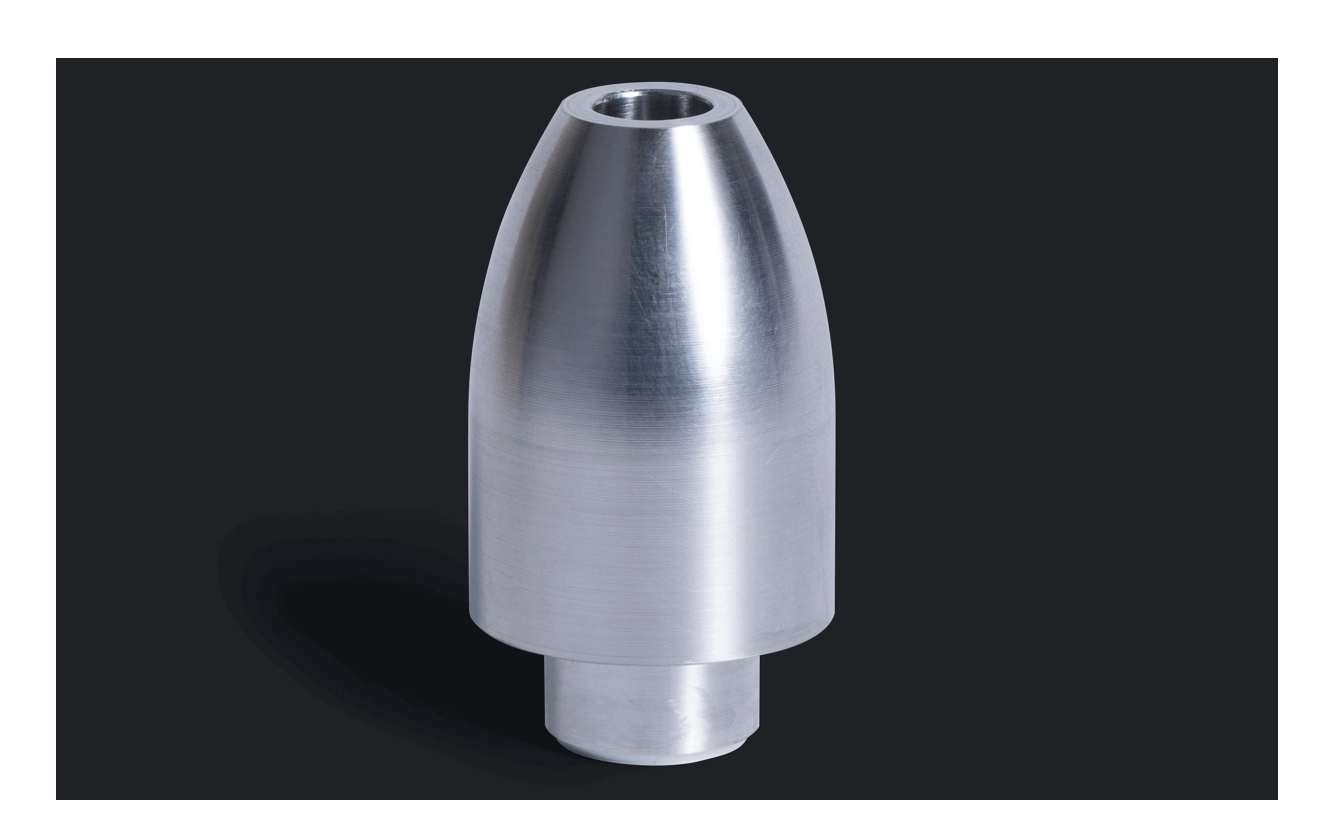

Aluminum 6061

Characteristic: Aluminum 6061 is the most common aluminum alloy, it has high strength-to-weight ratio, excellent machinability, and good corrosion resistance. It is also easy to weld and has good formability.

Lead Time: As fast as 3 days

Finishing Options: Bead blasting, Anodizing, Hardcoat Anodizing, Conductive Anodizing, Brushing, Silkscreen, Laser marking, Hand Polishing. Learn more >

Aluminum 7075

Characteristic: Aluminum 7075 is an aerospace-grade material often used in applications that require strong mechanical properties. It has excellent fatigue properties, high strength-to-weight ratio and hardness comparable to steels.

Lead Time: As fast as 3 days

Finishing Options: Bead blasting, Anodizing, Hardcoat Anodizing, Conductive Anodizing, Brushing, Silkscreen, Laser marking, Hand Polishing. Learn more >

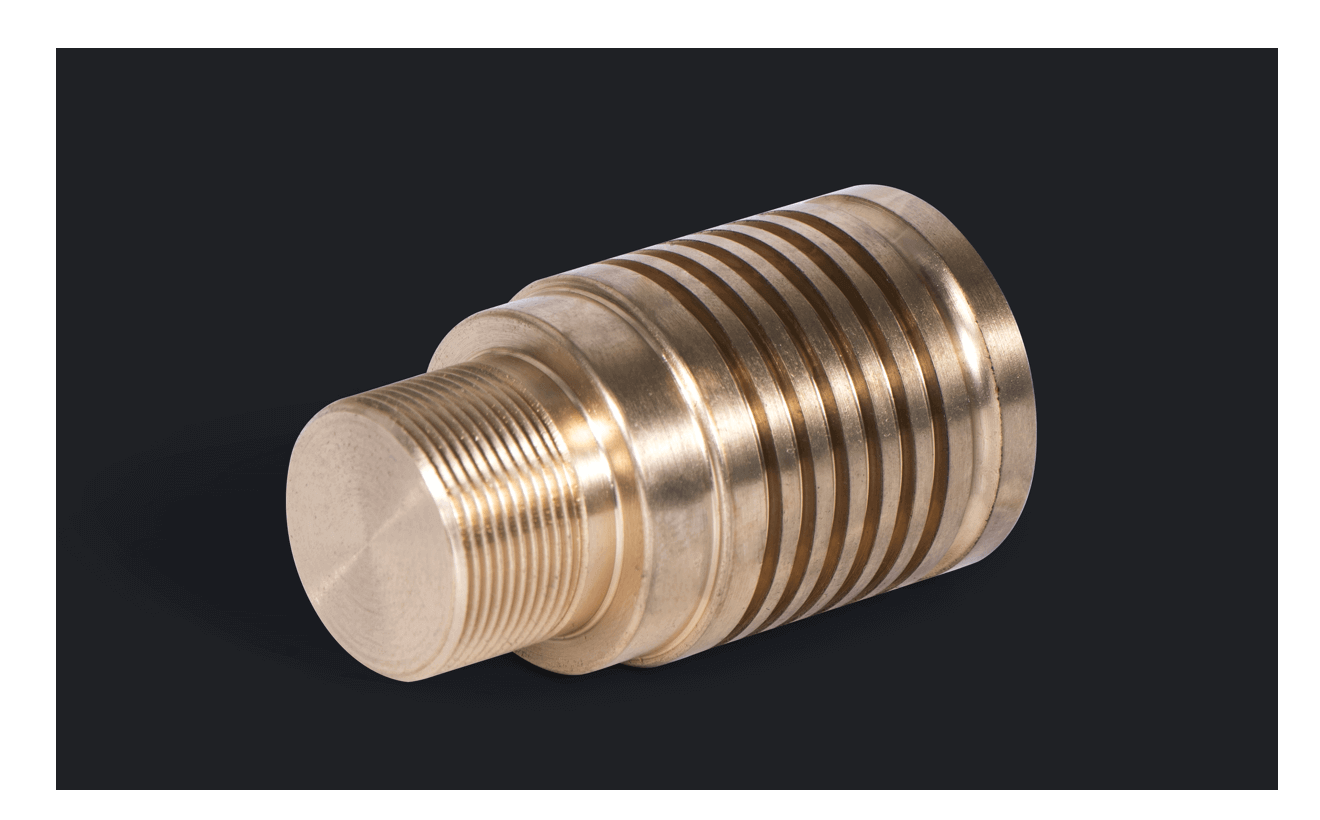

Brass - H59

Characteristic: Brass is a metal alloy with good machinability and excellent electrical conductivity. It is often used in low-friction, decorative and functional applications due to its attractive appearance and good corrosion resistance.

Lead Time: As fast as 4 days

Finishing Options: Bead blasting, Silkscreen, Laser marking, Hand Polishing, Mirror Polishing. Learn more >

Copper - T2

Characteristic: T2 copper has good electrical and thermal conductivity, corrosion resistance, polishing performance and surface treatment properties. It is widely used in electrical industries. Mainly used in decorative panels, heat exchangers, radiators, valves, and electrical connectors.

Lead Time: As fast as 4 days

Finishing Options: Bead blasting, Silkscreen, Laser marking, Hand Polishing, Mirror Polishing. Learn more >

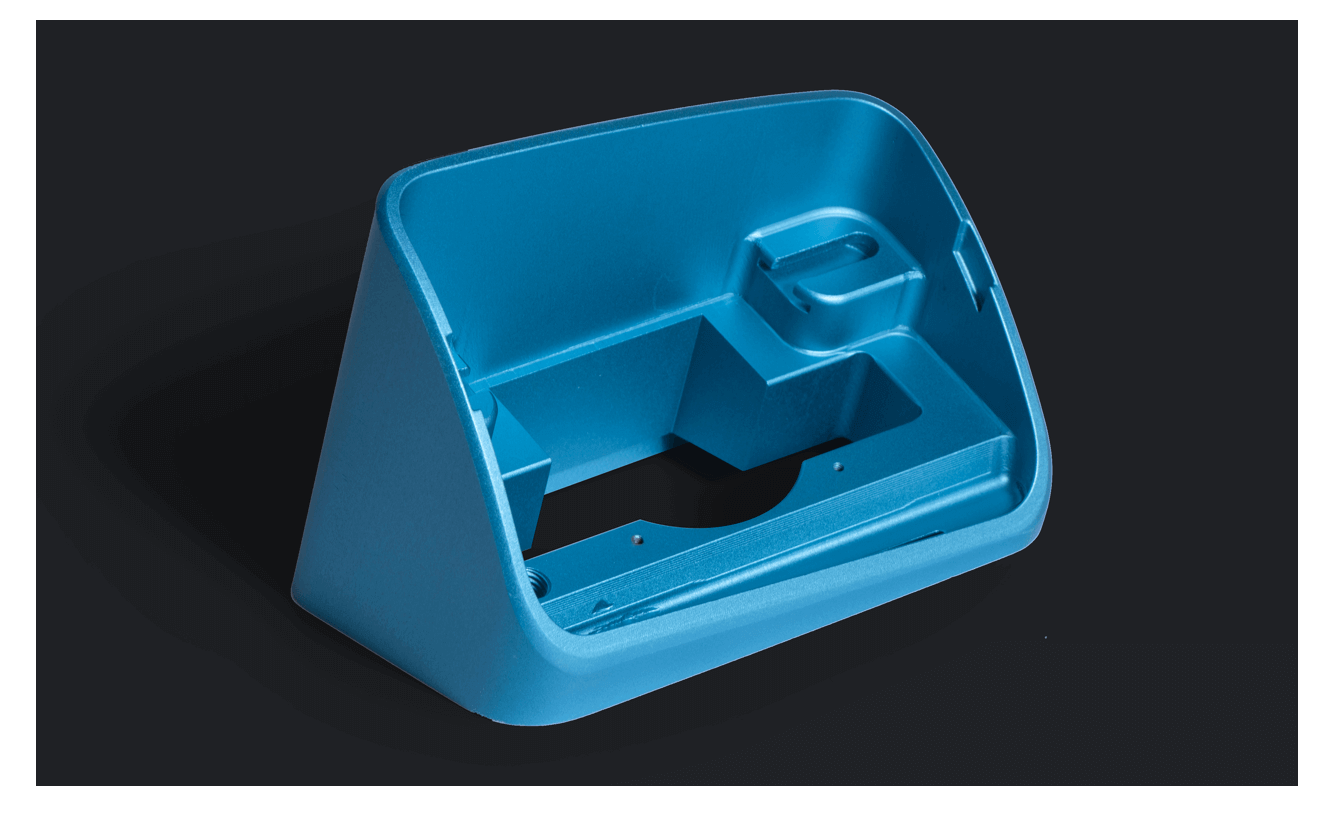

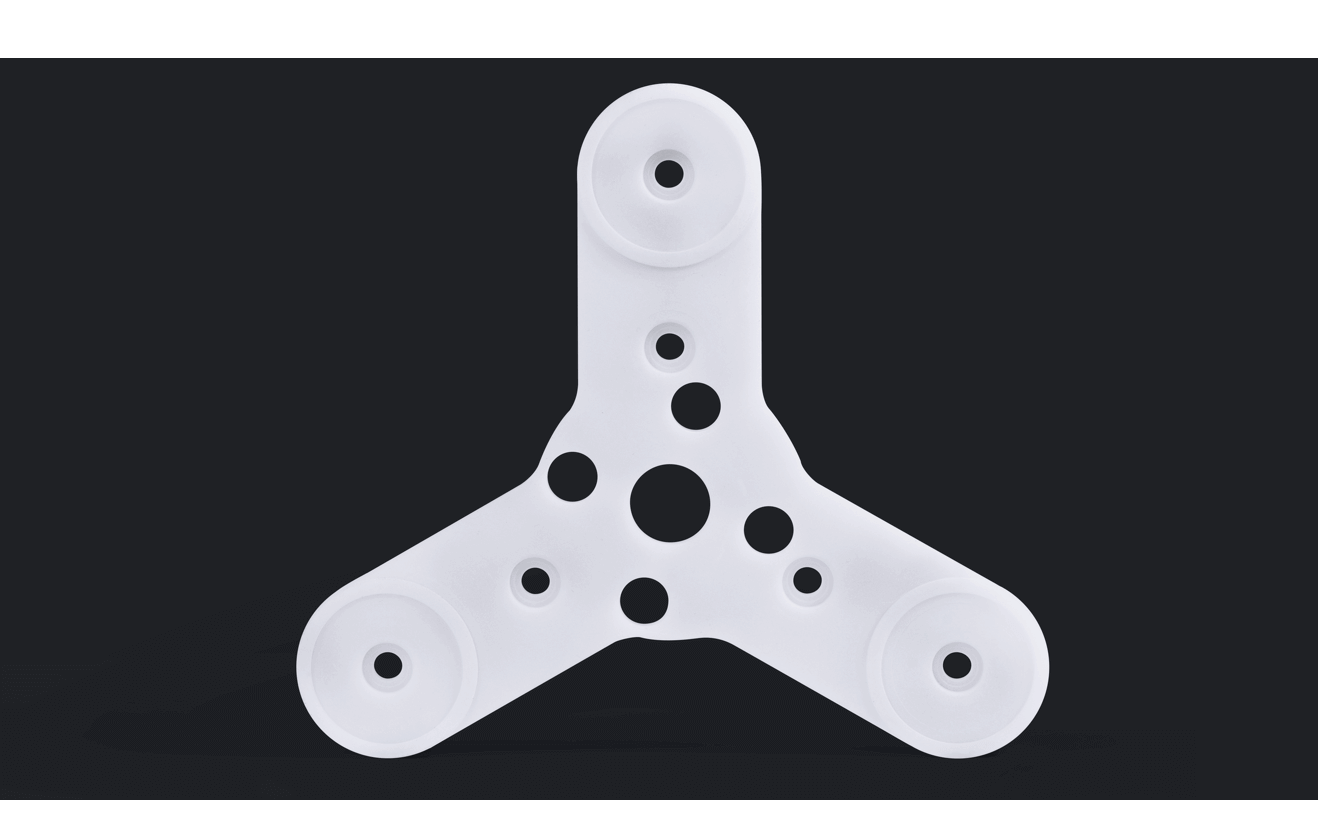

ABS

Characteristic: ABS is a common thermoplastic material, it has excellent impact resistance, good dimensional stability, and low cost. ABS has low density, making it ideal for lightweight applications. ABS parts are often used as prototypes prior to mass-production with injection molding.

Lead Time: As fast as 3 days

Finishing Options: Bead blasting, Silkscreen, Laser marking, Hand Polishing. Learn more >

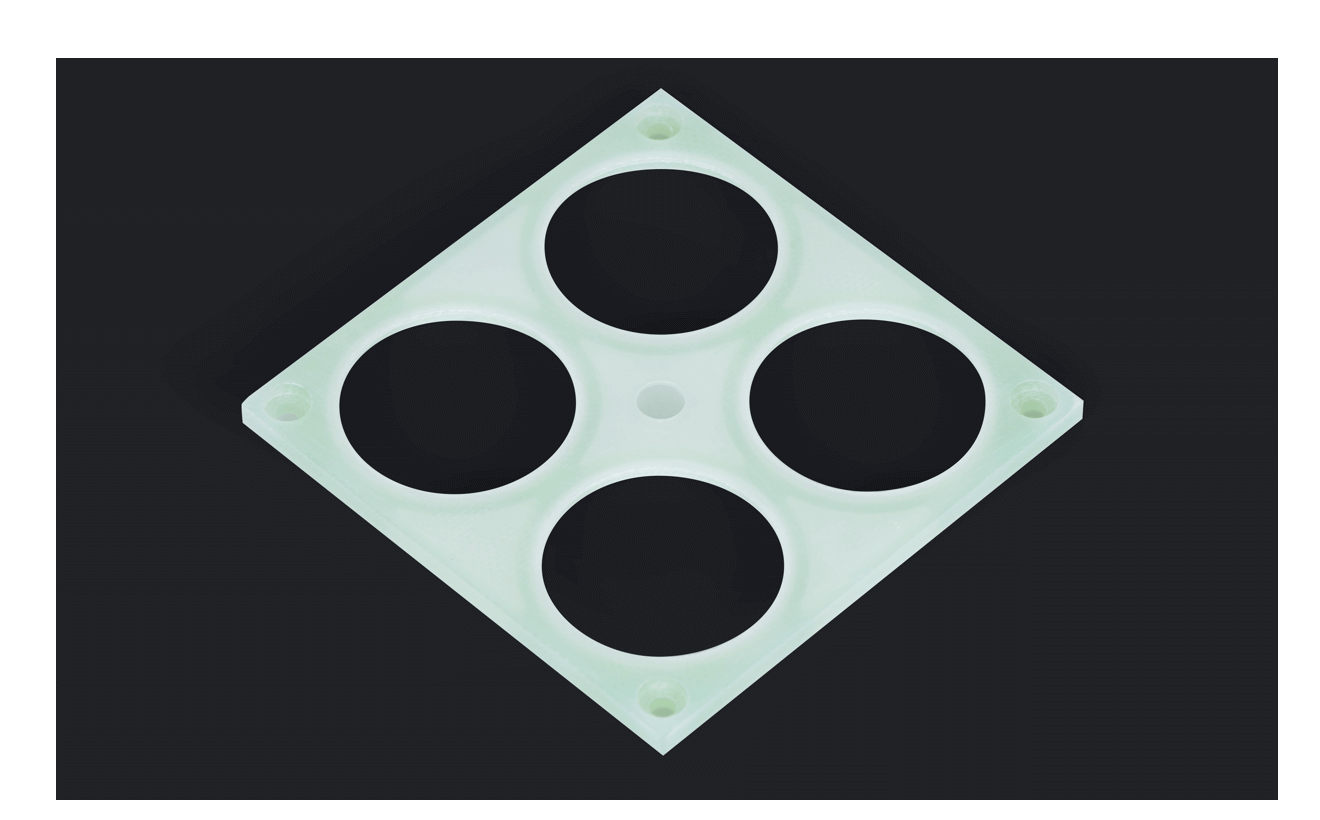

FR4

Characteristic: FR4 is an electrical-grade, dielectric fiberglass laminate epoxy resin system combined with a glass fabric substrate. It has extremely high mechanical strength, good dielectric loss properties, and good electric strength properties.

Lead Time: As fast as 3 days

Finishing Options: Silkscreen, Laser marking, Hand Polishing. Learn more >

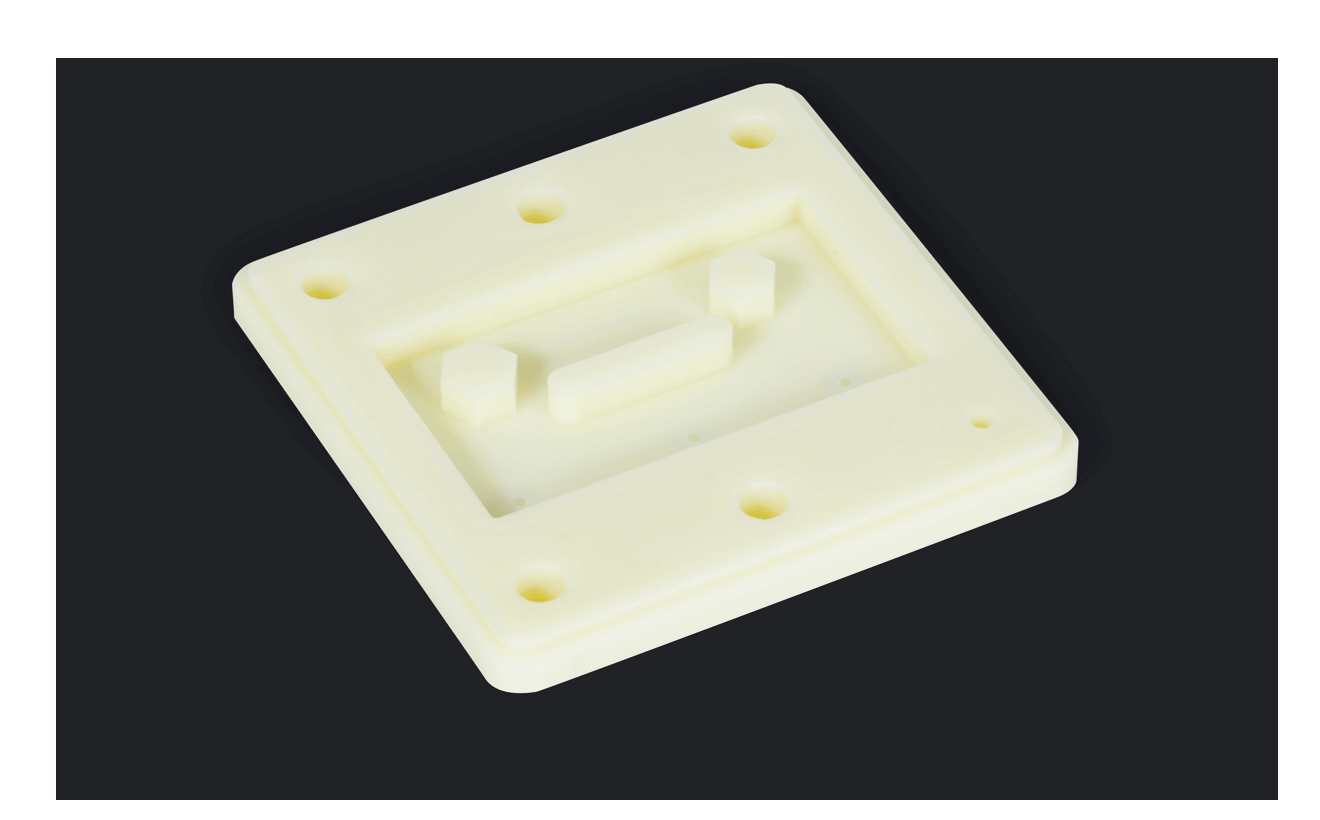

Nylon-PA6

Characteristic: Nylon PA6 is a high-strength material that is often used in applications that require good wear resistance, high toughness, and low friction. It is also resistant to chemicals and has good electrical insulation properties.

Lead Time: As fast as 3 days

Finishing Options: Finishing Options: Bead blasting, Silkscreen, Laser marking, Hand Polishing. Learn more >

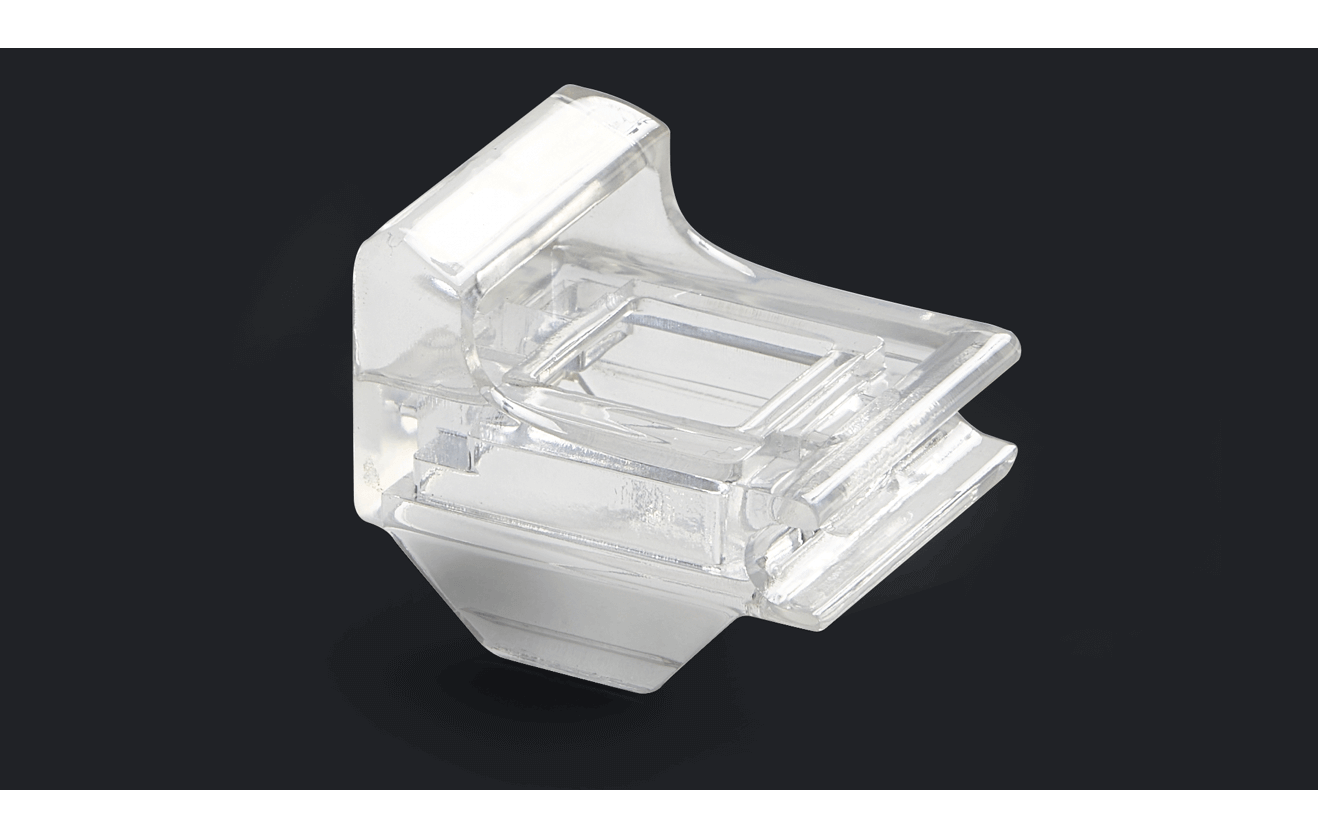

Polycarbonate

Characteristic: Polycarbonate is a thermoplastic with high toughness, good machinability, good transparency and excellent impact strength (better than ABS). It is also resistant to heat, chemicals, and weathering.

Lead Time: As fast as 3 days

Finishing Options: Bead blasting, Silkscreen, Laser marking, Hand Polishing, Vapor Polishing. Learn more >

PMMA

Characteristic: PMMA(Acrylic) is an optically clear, lightweight, and UV-stable plastic that exhibits excellent strength and stiffness, often used as a substitute for glass. Acrylic machining is widely used in the automotive industry as well as in the test and measurement industry.

Lead Time: As fast as 3 days

Finishing Options: Bead blasting, Silkscreen, Laser marking, Hand Polishing, Vapor Polishing. Learn more >

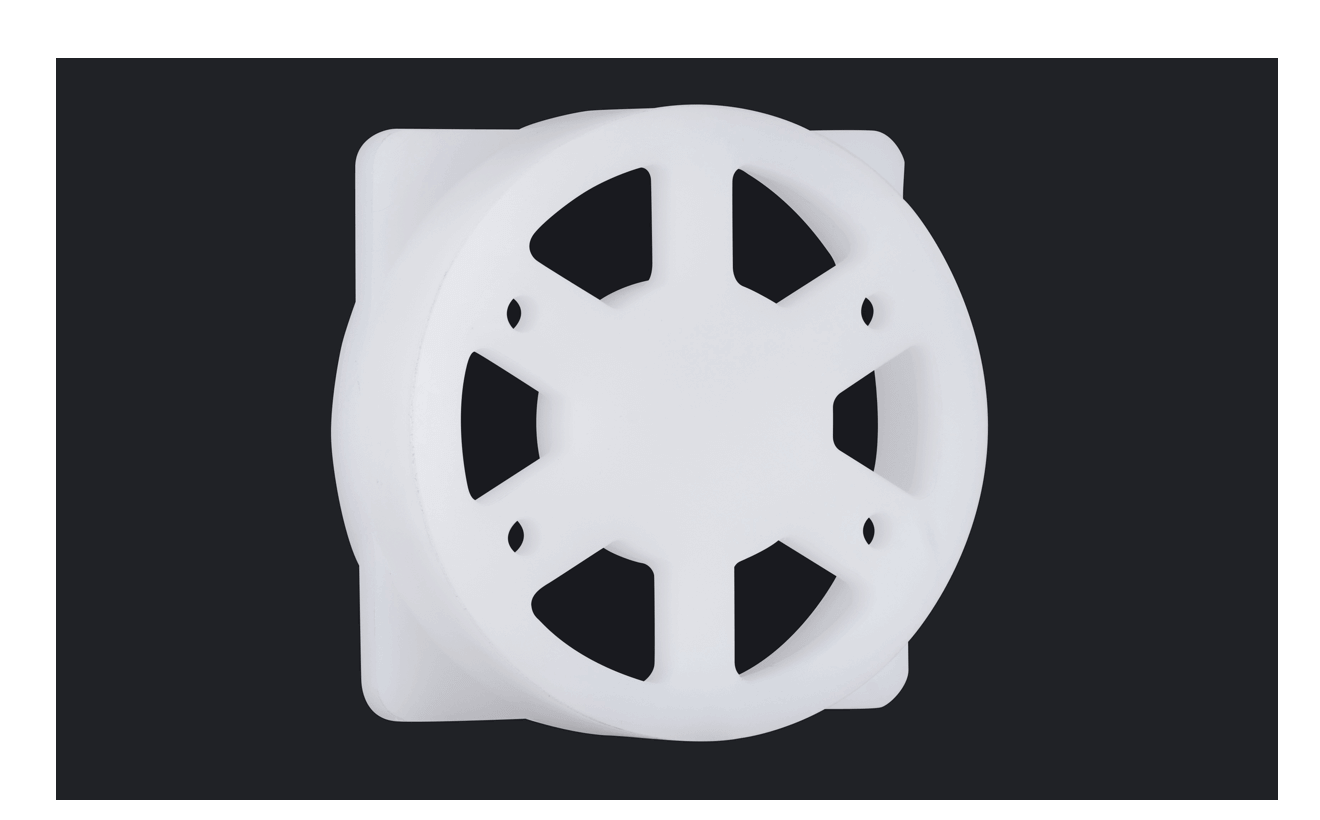

POM

Characteristic: POM is an engineering thermoplastic used in precision parts requiring high stiffness, low friction, and excellent dimensional stability.

Lead Time: As fast as 3 days

Finishing Options: Bead blasting Learn more >

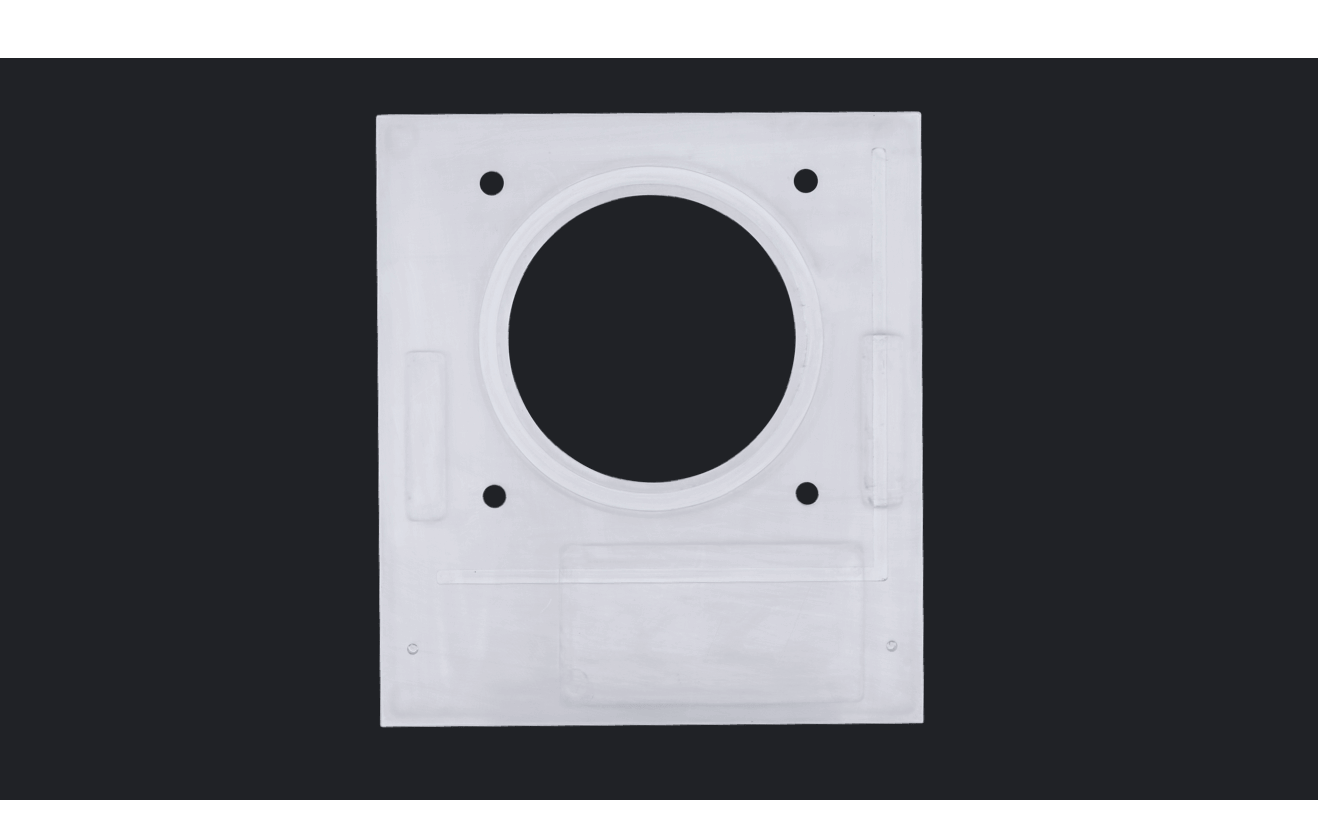

Polypropylene

Characteristic: Polypropylene (PP) resists most solvents and chemicals, which makes it a wonderful material to manufacture laboratory equipment and containers for a variety of applications. PP also offers good fatigue strength.

Lead Time: As fast as 3 days

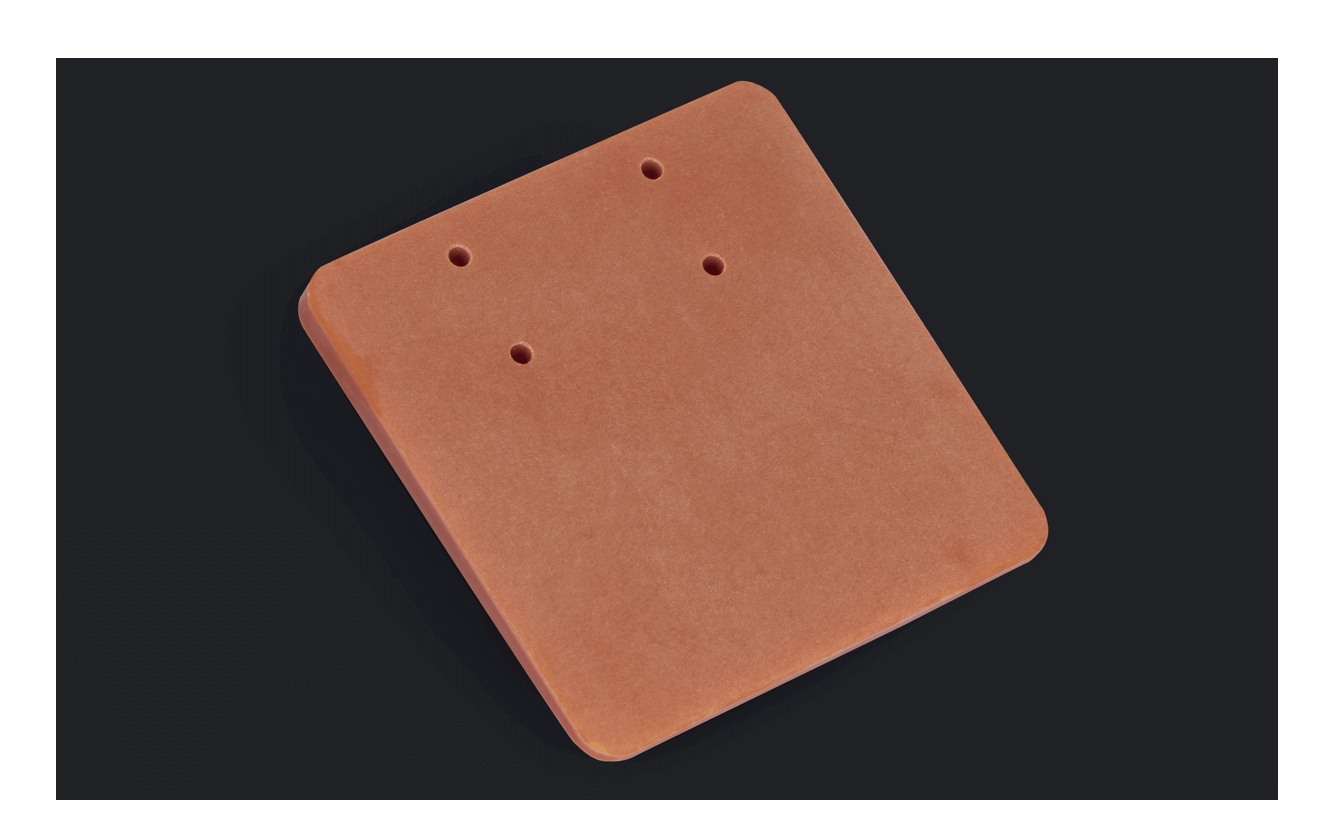

Bakelite

Characteristic: Bakelite is a hard, dense material with high tensile strength, low moisture absorption, and excellent electrical insulation properties. It is often used in applications where these properties are important, such as electrical switches, sockets, and connectors.

Lead Time: As fast as 3 days

- Plastic

- ABS • <

- FR4 • <

- Nylon-PA6 • <

- Polycarbonate • <

- PMMA • <

- POM • <

- Polypropylene • <

- Bakelite • <

CNC Machining Surface Finishes

As machined

Parts are machined and deburred, sharp edges are chamfered. Visible machining marks, light surface scratches.Bead blasting

Parts are bead blasted with glass beads which results in smooth, matte appearance and reduced machining marks.Brushing

Parts are brushed using an abrasive tool to create a pattern of fine parallel lines on the material surface, producing a unique aesthetic effect.Anodizing

Anodizing creates a corrosion-resistant, uniform, matte or glossy finish. Parts can be anodized in different colors—black, red, and gold are most common.Hardcoat anodizing

A type of anodizing that produces a thicker and harder coating on the surface, resulting in increased wear resistance and durability.Conductive anodizing

An anodizing process that creates a conductive oxide layer on the surface, typically used for EMI/RFI shielding or electrical grounding applications.Hand Polishing

A manual polishing process that uses abrasive tools and compounds to remove surface imperfections and produce a smooth, shiny surface finish.Vapor Polishing

Vapor polishing can create a near-optically clear surface finish and is commonly used in applications where high levels of transparency are required.Mirror Polishing

A surface finishing process that uses a series of increasingly fine abrasive tools and compounds to produce a highly reflective, mirror-like surface finish.Silkscreen

A part marking technique that uses a fine mesh screen to apply ink onto a surface, to print the desired text or image onto the substrate.Laser marking

Laser marking uses a laser beam to create permanent marks or designs on the surface of a material, typically resulting in high precision and resolution.